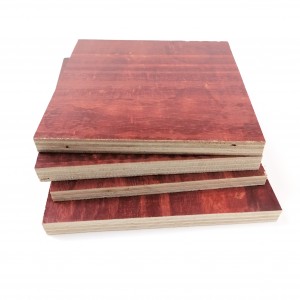

Construction dedicated hardwood core waterproof FILM FACED PLYWOOD

Video

Product Presentation

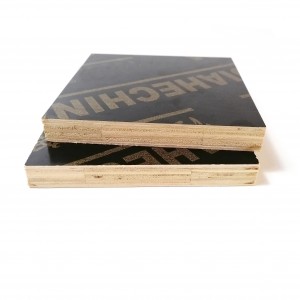

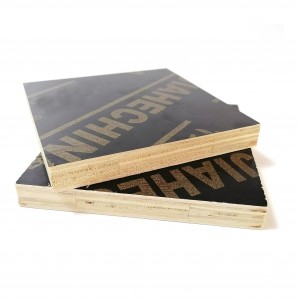

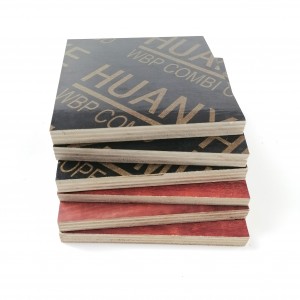

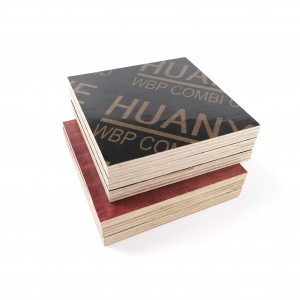

(1). Film color: brown, black or others

The most common membrane paper is brown or black. In China, brown film faced plywood is generally of better quality than black film faced plywood. However, this is not always the case. Some black film veneer plywood has the same quality as brown film veneer plywood. When you make an inquiry, an experienced salesperson will know what quality you really need.

(2). Film quality:

Construction template film paper is mainly divided into three types (1, impregnated film paper 2, PVC film paper 3, plastic film paper), ordinary Film faced plywood uses impregnated film paper, which is at a favorable price and meets the standard quality requirements. PVC/plastic film Paper is a high-end product, the quality is very good, usually up to 30 times of repeated use

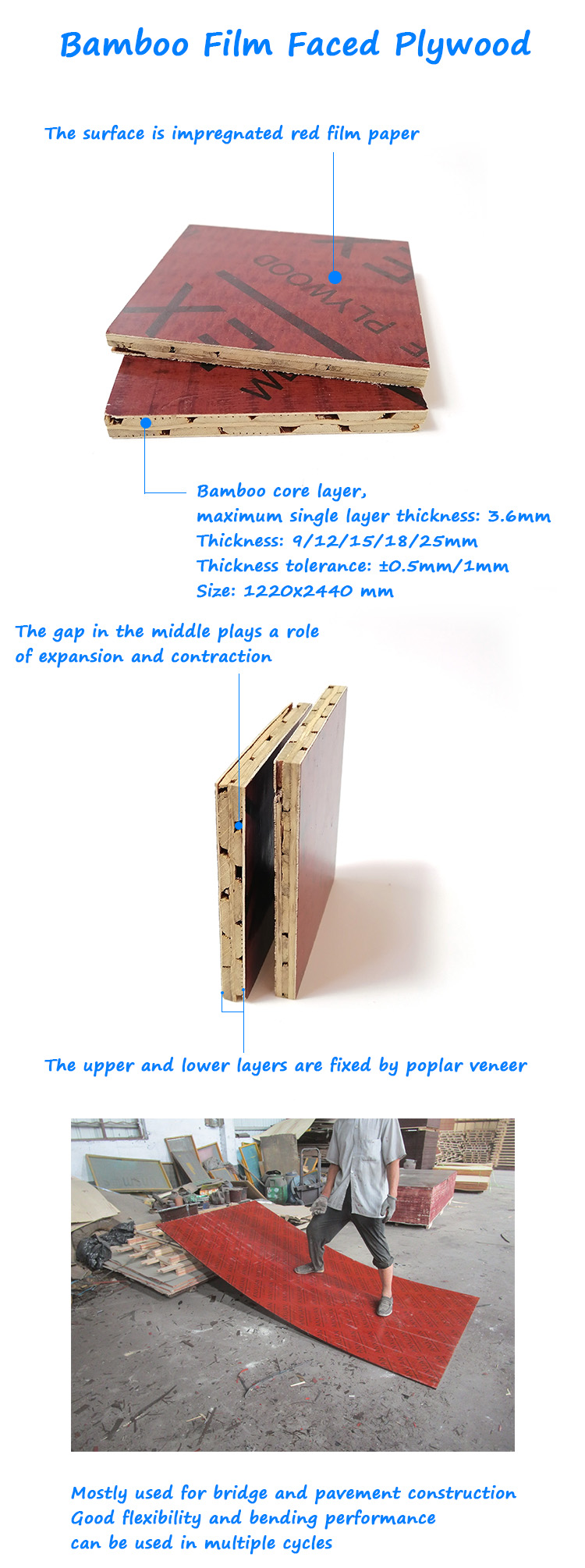

(3). Core: poplar, hardwood, Eucalyptus, pine, bamboo

70% of the film faced plywood sold in the market is poplar Film faced plywood, which is of high quality and competitive price. If you need hardwood laminated plywood, we will use hardwood or eucalyptus veneer. If you want to build bridges, you can choose bamboo Film faced plywood, which has certain flexibility and bending properties. If you need film plywood for high-rise buildings, you can choose hardwood Film faced plywood, as its name suggests Said it is very hard. We also offer pine Film faced plywood, which is also very hard and durable.

(3). Glue: MR glue, WBP(melamine), WBP(phenolic)

We use these 3 types of glue. As for the knowledge of the glue, you can refer to the following articles:

What’s MR glue-which is commonly used for plywood / film faced plywood / blockboard

What is WBP glue – which is commonly used for WBP plywood / film faced plywood

(4). Size: 1220X2440mm, 1250X2500mm, or 4′ x 8′, standard size, large size, big size, special size

We produce sizes according to customers’ requirement. The widest size can be 1830mm, max length is 2745mm.

(5).Thickness: 9mm-25mm (9mm / 12mm / 15mm /16mm/ 18mm / 20mm-25mm)

We can provide thickness tolerance in the range of ±0.2mm or even more accurate thickness, which is our advantage

(6).Packing: Standard Packing.

Standard export carton packaging, reconstituted wooden pallet

Samples

Product Parameters

| Model Number | 1220mmx2440mm/915mmx1830mm |

| Brand Name | YG WOOD |

| Usage | Construction |

| Main Material | Eucalyptus/poplar |

| Supply Ability | 5000 Cubic Meters per Month |

| Packaing Details | Standard export packing |

| Port | Qinzhou Port/Qindao Port/Lianyungang Port |

| Lead Time | 10 days |

| Grade | A grade or as client requirement |

| formaldehyde emission standards | Melamine OR WBP |

| Color | As client requirement |

| After-sale Service | Online Technical Suppor |

| Certification | CE, ISO9001,FSC,CARB |

| Moisture content | ≤12% |

Applications of Film Faced Plywood

(1) Construction industry: shuttering film faced plywood, concrete form, shuttering concrete form, formwork plywood

Film faced plywood is mainly used for construction. So film faced plywood is also called shuttering film faced plywood, concrete form, shuttering concrete form. Because of this end use, customers usually want WBP film faced plywood, which is more suitable to be used as shuttering for big projects. However, some customers require MR film faced plywood, which are to be used as shuttering for ordinary projects.

PVC/plastic plywood is reused more frequently and has a higher utilization

(2) Anti-slip film faced plywood: flooring materials for building vehicles, work platforms.

According to the types of face/back, film faced plywood can be divided into smooth film faced plywood and anti-slip film faced plywood. Anti-slip film faced plywood are usually used as flooring materials for vehicles, trucks and platforms.

(3) Film faced plywood can be used for shelves and furniture, too.

Compared with wood veneer faced plywood, film faced plywood is more durable and has more wear-resistant surfaces. So it can be used for making durable furniture and shelves.

(4) Bamboo Film faced plywood

Used for bridge construction or road construction. Due to the special structure of bamboo plywood, it can be bent and used, which greatly increases the practical performance

Product Application