Coffee Cup Paper Cup Fan for Hot And Cold drinking

Video

Overview

|

PRODUCT DESCRIPTION |

|

|

Product Name |

Paper cup fan |

|

Paper Weight |

150 ~ 350gsm |

|

PE Coated Weight |

10 ~ 30gsm |

|

Width |

Custom manufacturing |

|

Coating Side |

Single and double side |

|

Printing |

6 Colours flexo printing |

|

Use |

Raw material for paper cup, paper bowls,food boxs,etc |

|

Material |

100% virgin wood pulp |

|

Base Paper |

Yibin, App, Enso, Ningpo, etc. |

|

Size |

2~ 22OZ |

|

Feature |

Waterproof, oil-proof, resist high-temperature, clear printing |

|

Custom Order |

Accept |

|

MOQ |

5 tons |

|

Lead Time |

20-30 days |

|

FOB Port |

QINZHOU,GUANGZHOU,SHENZHEN |

Paper Cup Fan

* Professional manufacturer of PE coated paper.

* No impurities,neatly cut at both ends of surface, smooth surface.

Production Description

PAPER CUP FAN

Base Paper: 150 ~ 350gsm

PE Weight:10 ~30gsm

Material: Food grad

Certification: ISO,SGS,etc

Logo: According to customer requirements

Professional to provide raw materials for paper cups with one-stop service of laminating, printing, die-cutting and slitting.

Show Details

01. Food Grade Materials

1. Materials: Food grade PE materials

2. Base paper :100% Wood Pulp

3. Certified: SGS, Test Report No. Is GZAFF160910888ME

02. Product Feature

1. Waterproof, oil-proof, resist high-temperature, clear printing

03. Products Display

1. Easy to forming.

2. High quality of printing effect.

04. Products Display

1. Appearance: smooth surface, without breakage, tidy.

05. Products Display

1. Support matt lamination and bright lamination.

Applications

PE coated paper cup fan can be widely used to make a variety of products,such as

1.Paper cup. 2.Paper bowls 3. Food boxes,etc

Production Processing

1.Raw material→ 2. Material testing → 3.Laminating → 4.Flexo pringting → 5.Die cutting → 6. QC inspection→ 7.Packing finished → 8.Storage

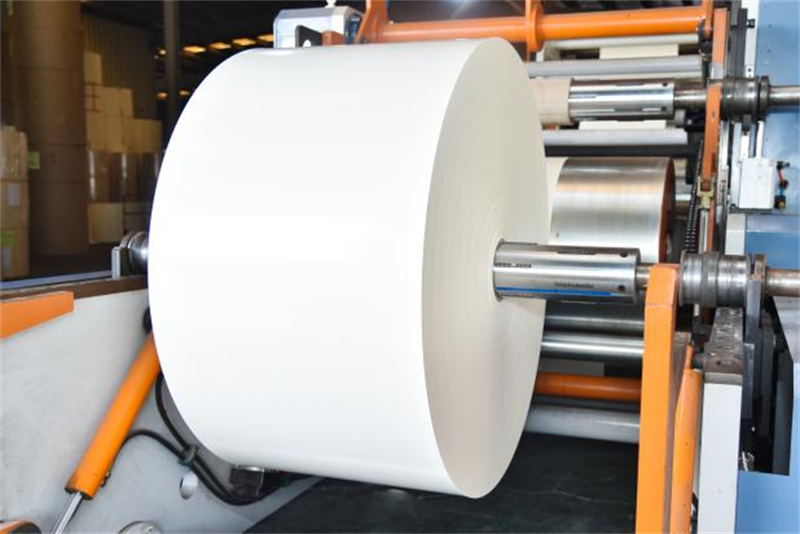

1. Raw material

2. Material testing

3. Laminating

4. Flexo pringting

5. Die cutting

6. QC inspection

7. Packing

8. Storage

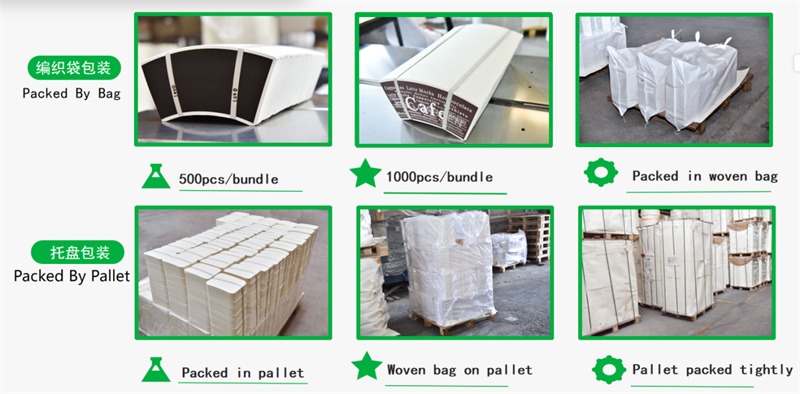

Packing Solution

There are three types of packing :packed by carton, by bag, by pallet.

Why choose us?