Pe Coated Krafte Paper Wood Pulp Food Grade Single and Double wall PE Coated For Paper Bag Paper Cup Paper bowl High Quality Factory Direct Sell

Overview

|

Overview |

|

|

Product Name |

PE coated kraft paper |

|

Paper Weight |

150~350gsm |

|

PE Coated Weight |

10~30gsm |

|

Width |

600~1500mm |

|

Coating Side |

Single and double side |

|

Core Dia |

3 inch , 6 inch |

|

Use |

Carton, food packaging, paper cup, paper bowl, cake boxes, etc |

|

Material |

100% Wood Pulp |

|

Feature |

Waterproof, greaseproof, resist high-temperature,high-burst, food grade, Good printing effect. |

|

Custom Order |

Accept |

|

MOQ |

5 tons |

|

Lead Time |

20-30 days after confirm the deposit |

|

FOB Port |

China port, such as QINZHOU,GUANGZHOU,SHENZHEN |

|

Printing |

Flexo and offset printing |

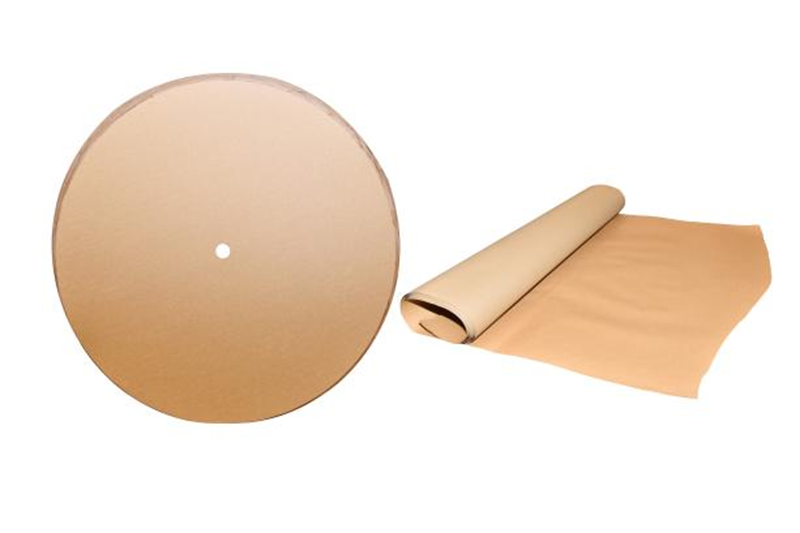

PE Coated Kraft Paper

* Green product,good quality, line world.

* Focus on eco-friendly products, creating better environment for our better life.

Production Description

PE coated kraft paper

Base Paper: 150 ~ 350gsm

PE Weight:10 - 30gsm

Roll Dia :1100 ~ 1600mm

Core Dia:3 inch and 6 inch

Width:600 ~ 1500mm

Eco Friendly High quality PE Coated Kraft Paper For making Paper Cup

|

Hot Drink Cup size |

Hot Drink Paper suggested |

Cold Drink Cup size |

Cold Drink Paper suggested |

|

3oz |

(150~170gsm)+15PE |

9oz |

(190~230gsm)+15PE+18PE |

|

4oz |

(160~180gsm)+15PE |

12oz |

(210~250gsm)+15PE+18PE |

|

6oz |

(170~190gsm)+15PE |

16oz |

(230~260gsm)+15PE+18PE |

|

7oz |

(190~210gsm)+15PE |

22oz |

(240~280gsm)+15PE+18PE |

|

9oz |

(190~230gsm)+15PE |

||

|

12oz |

(210~250gsm)+15PE |

Show Details

01. Food Grade Materials

Selection of food grade raw materials, reliable product quality.

1. Base paper :100% Wood Pulp.

2. Polyethylene Particles: Food grade.

02. Product Feature

1. Smooth and fine appearance, good stiffness, high firmness of PE coated film.

2. PE coated kraft paper with waterproof, damp proof, high-burst, food grade, good printing effect.

03. Products Detail

1. The products are made of pure wood pulp,natural-looking colour.

04. Products Detail

2. Coating Side: single side or double side with PE coated

05. Products Detail

1. Two types of lamination: matt or glossy lamination.

Applications

Applicability of PE coated paper can be widely used to make a variety of products.

For example, carton, food packaging, paper cup, cake boxes, etc

Production Processing

1. Bace paper → 2.Paper material testing → 3.PE coating processing → 4.PE coating finished → 5.QC inspection → 6.Packing finished

1. Top-quality bace paper

2. Bace paper material testing

3. PE coating processing

4. PE coating finished

5. QC inspection

6. Packing finished

Quality Control

Quality control is one of our very important procedure during the production.

PE coating quality control as below:

1. Bace paper testing

2. Coating machine inspection

3. PE coating fastness verification

4. Roll tidy verification

5. Roll weight verification

6. Packing verification

Packing Solution

1. Core:

The core dia of kraft paper roll is 3 inch core or 6 inch core .

2. Outer package :

We use Kraft paper for outer packing which is good to protect the paper roll.

3. Three layer of PE wrapped outside:

Three layers of PE packing is resistant to water, oil, dust and more. To keep the product dry and clean. The outer packing is strong enough for long distance shipments.

4. Palletizing:

Pallets makes the paper rolls to be much more easier for loading and unloading.

1. Paper core and wooden cork inside

2. Kraft paper outer packing

3. Three layers of PE packing

4. Palletizing

Trade procedure?

1. Make offers: We'll send you a quote without delay, ensure the timeliest supply of quote.

2. Send the free sample: Quotations and samples will be sent upon receipt of your specific inquiries .

3. Place an order: Customers place orders according to samples.

4. Delivery control: We confirm the delivery date to the customer according to the production capacity.

5. Quality control: Strictly control every link of production.

6. Deliver good: The goods are dispatched to the port.

Show Strength

Fast delivery: advanced production lines, adequate stocking and shorten the delivery time!

1. Bird's Eye View

2. Professional Transport

3. Auto-high speed lamination machine.